Panned products development and batch testing

You want to develop a sugar, sugar free or chocolate panned product ?

Whether you are an industrial manufacturer or professional artisan, you will need to carry out trials on the small scale before manufacturing batch scale.

His knowledge of recipes, his master of crystallization reactions (fat material or sugar) and his experience in developing panned products, will enable Frédéric Menguy to help you reach objectives more quickly.

Possibilities in case of panned product development

- In-house batch testing development,

- External batch testing development in our Application Laboratory,

- Prototype creation in our Application Laboratory

In case of factory or workshop creation, FMDE, the structure of Frédéric Menguy, can help you to create your own test laboratory

FMDE can also help you to equip you with a panning pilot plant while considering your budget.

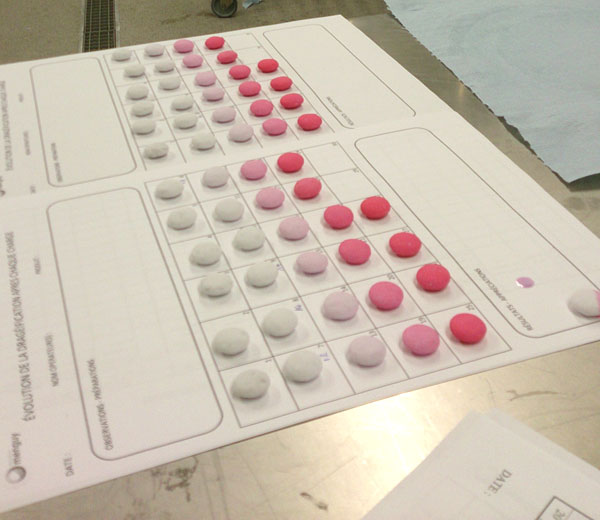

An example of a problem to solve

Find a substitute of titanium dioxide in panning process

The request to substitute titanium dioxide in confectionary is growing. Suspected to be carcinogenic, the titanium dioxide could quickly become a «cumbersome friend» for the confectioner. Research will progress, one way or another, but in the meantime the confectioner cannot sit around waiting. Moreover even if the titanium dioxide was revealed safe, the real arbitrator of the final decision will be the consumer. And in this field, we all know that the choices

are not always rational.

Consequently we can try to educate the consumer by making him accept a lower visual quality but it would be more cautious to look for alternative to titanium dioxide as of today.

Why is titanium dioxide so hard to replace ?

It is greatly appreciated by panners because it improves several aspects :

- By its opacifying properties, it enables a true white layer. Without this, the layer of sugar is yellowish.

- In the case of coloured dragées, it enables to have a true white base which is necessary for brightness of colours, especially for light colours.

- In the pan, it will enable by its molecular structure, to improve sliding of the centres. Some panners consider it helps to keep the edges and contributes to decrease the rate of waste.

fishbone diagram

In the same way as problem solving, we could use the fishbone diagram to find and prioritize solutions to substitute titanium dioxide.

So we will notice that raw material parameter is not the only one to consider. Method, Material, but also Manpower. Some examples :

| Origin | Lever | Possible action to realize |

|---|---|---|

| Method | Lack of drying | • Increase drying time • Reduce load • Increase brix of the sugar syrup |

| Method | Too high quantity | • Decrease dosage in the sugar syrup • Begin panning process without titanium dioxide • Change organization of the production |

| Machine | Lack of drying | • Increase efficiency of the air treatment installation • Improve flow and absolute humidity of the drying air |

| Manpower | Habits | • Change habits by modifying practices • Develop risk awareness both for the consumers and themselves. • FFP2S masks must be worn by operators. |

The raw material parameter is of course the most important.

Even if solutions exist today, none of them can give result as good as titanium dioxide. We can consider using a combination of several materials :

- Calcium carbonate

- Sucroester

- Rice starc

- Ready to use solutions developed by ingredient suppliers

- …

In conclusion

The substitution of titanium dioxide must be a real approach in the development of new panned products.

Once again, Frédéric Menguy will be able to help you find the best compromise between Marketing and production. The impact of modification on costs, labelling or production organisation will be evaluated.

Do you have a project ?

Get an expert to develop your sugar, sugar-free or chocolate panned product?

Today recognized as one of the best experts in pan coating, he guides industrial confectioners and artisan chocolatiers in their development in France as well as internationally.